Rust is a significant concern for Columbus, OH, affecting everything from bridges and buildings to industrial equipment. Hot-dip galvanizing offers a powerful solution, providing long-lasting corrosion protection. This comprehensive guide explains the process, its benefits, and how to find reputable galvanizers in the Columbus area. We'll cover everything from the technical details to choosing the right partner for your project.

Understanding Hot-Dip Galvanizing

Hot-dip galvanizing is a process that significantly extends the lifespan of steel components by creating a metallurgical bond between the steel and a layer of zinc. Unlike paint, which merely coats the surface, the zinc fuses with the steel, offering deep, lasting protection against rust and corrosion. This is particularly crucial in Columbus, where varying weather conditions demand robust corrosion resistance.

The Process: A Detailed Look

The hot-dip galvanizing process involves several key steps:

- Cleaning: The steel is meticulously cleaned to remove any dirt, grease, or mill scale, ensuring optimal adhesion of the zinc coating. Imperfect cleaning can significantly reduce the effectiveness of the process.

- Fluxing: A chemical flux is applied to facilitate the bonding process between the steel and the zinc, promoting a strong and even coating.

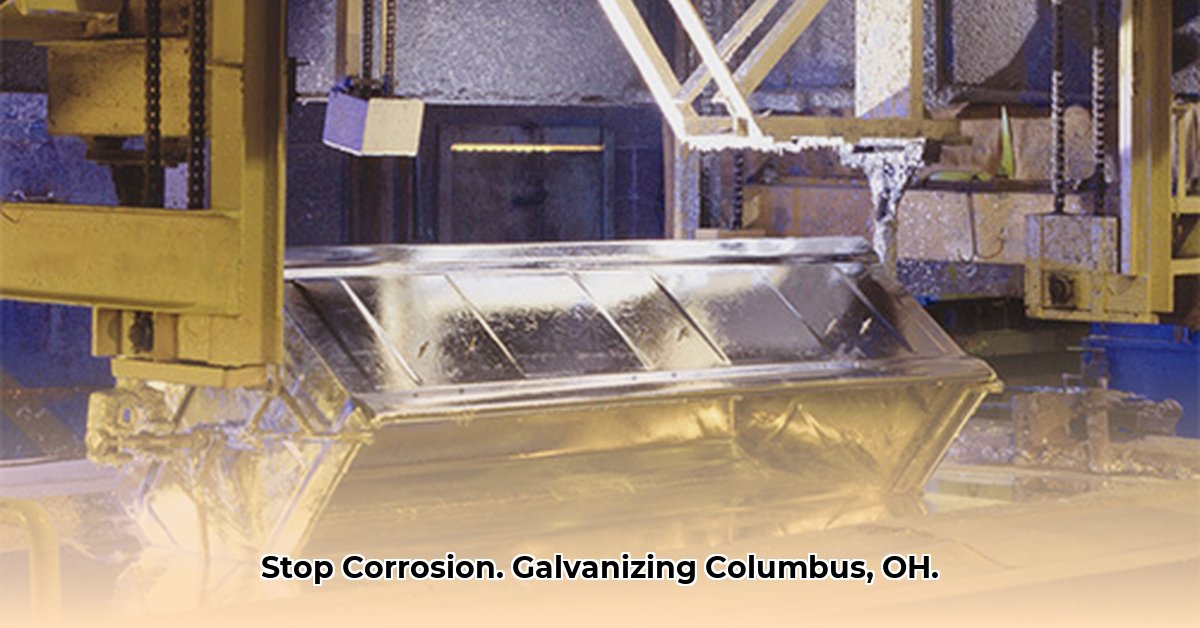

- Hot Dip: The cleaned steel is submerged in a bath of molten zinc, typically around 840°F (449°C). This high temperature allows the zinc to fuse with the steel, creating a protective layer.

- Cooling and Inspection: After the dipping process, the steel cools, and the finished product undergoes rigorous quality inspection to ensure the galvanizing process has been completed effectively and meets industry standards.

Benefits of Hot-Dip Galvanizing

Hot-dip galvanizing offers substantial advantages over other corrosion protection methods:

- Exceptional Durability: The zinc coating provides decades, even centuries, of protection against rust and corrosion, significantly extending the lifespan of steel components. Isn't long-term protection a worthwhile investment?

- Cost-Effectiveness: While the initial cost might be higher, the long-term savings from reduced maintenance and replacement costs often outweigh the upfront investment. How much would repeated repairs and replacements cost over the lifetime of a structure?

- Environmental Responsibility: The zinc coating is highly recyclable, and the reduced need for frequent replacements minimizes environmental impact. Isn't sustainable infrastructure a crucial societal priority?

- Versatility: The process accommodates a wide range of steel shapes and sizes, making it suitable for diverse applications.

However, it's important to consider potential drawbacks:

- Appearance: The textured appearance of the galvanized coating might not be aesthetically pleasing in all applications. But functional benefits often outweigh aesthetic concerns.

- Hydrogen Embrittlement: In specific cases, the process may cause minimal hydrogen embrittlement, which reduces steel ductility. Experienced galvanizers address this through careful process control.

Finding a Reputable Galvanizer in Columbus, OH

Selecting a reliable galvanizer is essential for optimal results. Consider these factors:

- Certifications: Look for certifications from relevant industry organizations, ensuring adherence to quality standards and industry best practices. What certifications signify a galvanizer's commitment to quality?

- Experience: Research the company's track record, seeking testimonials and reviews from past clients. What is their history of successful projects?

- Pre- and Post-Treatment Processes: Inquire about their pre-treatment (steel preparation) and post-treatment (handling procedures) procedures, as these are crucial for optimal results. What steps do they take to ensure the durability of the zinc layer?

Applications of Galvanizing in Columbus

Hot-dip galvanizing protects a vast array of structures in Columbus:

- Infrastructure: Bridges, road structures, and guardrails rely on galvanizing for long-term durability and safety.

- Buildings: Many buildings use galvanized steel in structural components and architectural elements. How much of Columbus' infrastructure relies on galvanized steel?

- Industrial settings: Industrial equipment, storage tanks, and various components benefit from the corrosion resistance provided by galvanizing.

Environmental Considerations and Best Practices

Responsible galvanizing practices minimize environmental impact. Compliance with local and federal regulations—including those dictated by the Ohio EPA—is paramount. Proper waste management and adherence to industry best practices contribute to environmental sustainability. How does the responsible use of hot-dip galvanizing impact the environment?

Conclusion: Securing Columbus' Future

Hot-dip galvanizing is a critical component of infrastructure protection in Columbus, OH, ensuring the long-term durability and safety of bridges, buildings, and industrial assets. By understanding the process, its benefits, and choosing a qualified galvanizer, we contribute to a more resilient and environmentally responsible city.